Applications

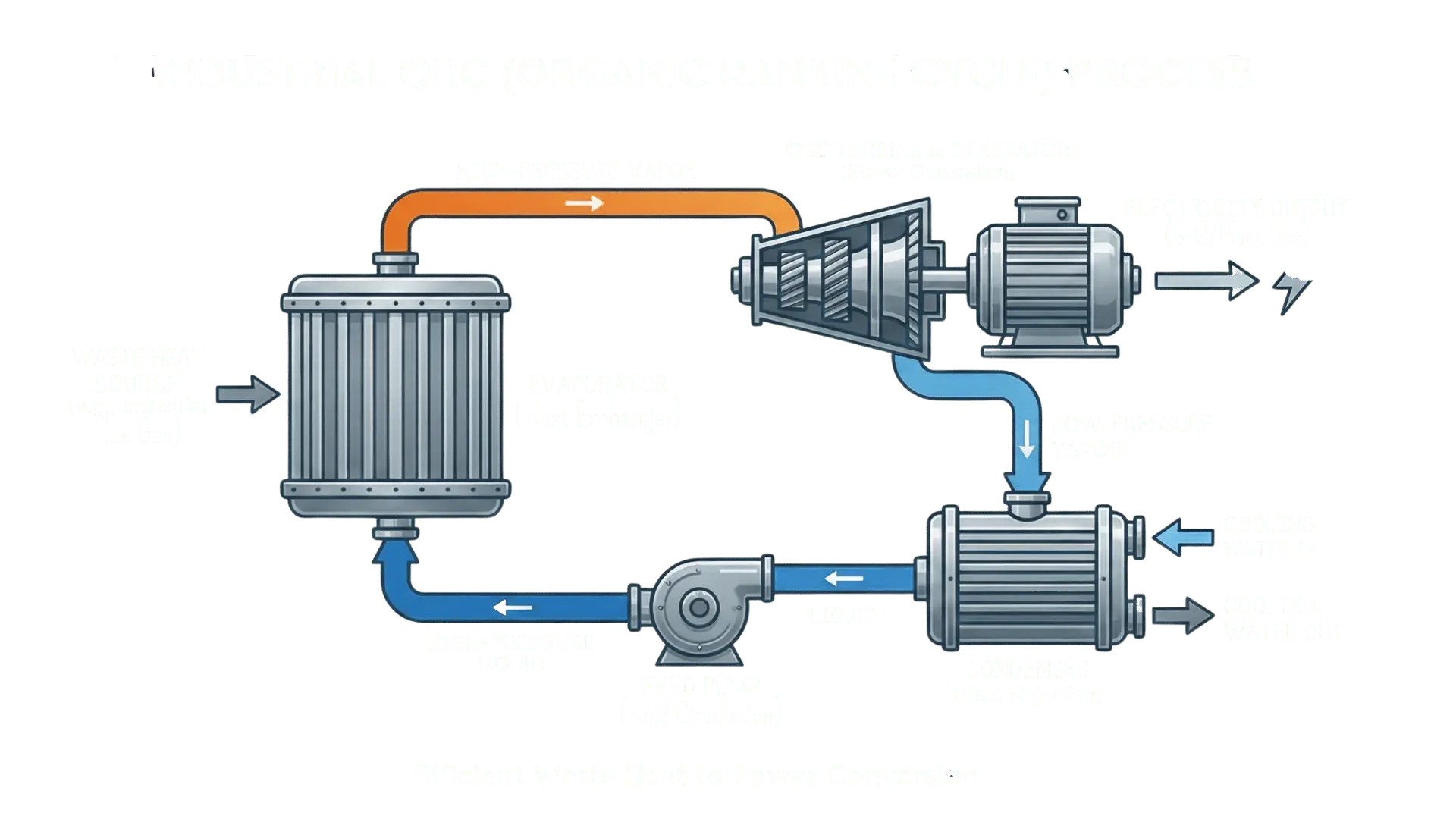

Our Heat to Power systems has range of applications from industrial waste heat recovery to biomass and geothermal resources to marine and engine-based energy recovery, and other thermal energy sources where electricity can be generated on-site.

Unlocking

Clean Energy

From

Waste Heat

Unlocking

Clean Energy

From

Waste Heat

Unlocking

Clean Energy

From

Waste Heat

Unlocking

Clean Energy

From

Waste Heat

Efficiency from lost heat in industrial processes.

Industrial facilities release significant recoverable heat through exhaust gases, hot liquids, and process streams. HrimTron systems turn these losses into dependable electricity.

- Boiler and thermic fluid heater exhaust

- Furnaces, kilns, ovens, dryers

- Steel, cement, and glass process flows

- Chemical process exhausts

- Heat source temperature: ~150–450°C

- Electrical output: 25 kWe–500 kWe (modular)

- Lower energy costs

- Reduced grid dependency

- Improved plant energy efficiency

- Lower CO₂ intensity per unit output

Continuous Baseload Renewable Power From Ground Heat

Geothermal resources offer stable heat well suited for ORC-based generation, especially in fields where temperatures are too low for steam cycles.

- Low-enthalpy wells

- Binary geothermal plants

- District or industrial geothermal networks

- Resource temperature: ~120–220°C

- Capacity factor: >90% achievable

- Renewable, fuel-free baseload power

- Modular expansion

- High availability, low operational complexity

Recovering onboard thermal losses for auxiliary power.

Marine engines and auxiliaries reject large amounts of heat through exhaust and cooling circuits. HrimTron systems harness this heat to deliver onboard electrical output, reducing fuel consumption and emissions.

- Main engine exhaust

- Auxiliary engine exhaust & jacket water

- Generator sets

- Exhaust/cooling heat: 180–400°C

- Lower fuel operating costs

- Reduced emissions per nautical mile

- Compliance support with evolving maritime standards

Power from renewable thermal sources

Biomass combustion and gasification produce stable thermal energy streams. HrimTron systems convert that energy into electrical power without steam turbines.

- Biomass boilers & CHP plants

- Agricultural residue thermal loops

- Waste-to-energy applications

- Heat source temperature: 200–450°C

- Renewable dispatchable power

- Simplified operation vs steam systems

- Scalable with biomass feedstock

Tapping residual heat in conventional and combined cycle plants.

Power generation plants reject heat through flue gas, cooling circuits, and turbine exhaust. HrimTron systems capture this available thermal energy to augment plant electrical output.

- Gas turbine exhaust

- HRSG outlets

- Condenser / cooling water circuits

- Boiler flue gas

- Heat source temperature: 180–500°C

- ncremental generation from existing plants

- Increased plant heat rate efficiency

- Reduced fuel burn per kWh

Leveraging low-temperature sources for power generation

Cold energy from cryogenic processes such as LNG regasification or industrial refrigeration can be harnessed via ORC systems designed for low-temperature differential operations. HrimTron systems capture this lost cooling potential and generate power where traditional turbine technologies are ineffective.

- LNG regasification cold streams

- Industrial cold storage heat rejection

- Refrigeration plant second-law recovery

- Temperature gradients: from sub-ambient to –50°C up to 150°C on the hot side

- Value from otherwise discarded cooling potential

- Enhanced plant energy balance

- Adds power without increasing heat input

Which Application Fits Your Site?

Your process may contain a combination of usable heat or cold streams. Share your heat/cold source data with us and our engineering team will evaluate feasibility and recommend the optimal HrimTron Performance system for your application.

Your process may contain a combination of usable heat or cold streams. Share your heat/cold source data with us and our engineering team will evaluate feasibility and recommend the optimal HrimTron Performance system for your application.